Challenges in the automotive industry and how Helmut Fischer addresses them

The automotive industry is constantly facing technology challenges to further improve the quality of its products. It can be difficult to find suppliers and partners who are aligned with these technological challenges. Helmut Fischer, as a global partner of the leading car manufacturers, offers the best technologies for measuring the thickness of coatings, satisfying a broad range of industry requirements.

Measuring applications in the automotive industry need to satisfy a number of requirements. These include layer measurement in hard-to-reach locations in coachwork interiors, on rough substrates, duplex coatings (paint / zinc on steel or iron) and reporting the results individually, as well as the measuring of coating while still hot as examples.

Applications of tri-cationic phosphate or Zn phosphate, electrodeposited coatings of Zn, ZnNi, Cr, Ni, Cu, NiP, among others, as well as powder paint coatings, coating by immersion or electrostatic painting, known as Catophoretic Coating (KTL), are some of the many applications that can easily be met by Fischer solutions.

Another important factor in the automotive industry is compliance with the standards of its service providers.

All parts need to meet specific quality control requirements, and measurements must be certified and traceable in compliance with standards such as:

- ISO 17025

- IATF 16949

- ISO 9001

Achieving high precision in manufacturing processes while optimising costs is a persistent challenge for the automotive industry.

An example of how we can support cost optimisation: Helmut Fischer equipment enables control of the element composition of galvanic baths. This allows better control of the thickness of the final layer by means of better process control, thereby ensuring quality and at the lowest possible cost.

Our high-performance equipment and analytical instruments surpass industry expectations in terms of precision and efficiency.

DMP® Series

The DMP Series of layer thickness gauges and our high-precision probes allow for non-destructive and highly accurate measurements of paint coatings and lacquers. Whether it’s for quality control in a manufacturing process, random sample inspection or complete batches, these portable, easy-to-use instruments will meet your needs. With more than 70 different types of probes, even the most challenging jobs, such as measuring on rough surfaces, in holes and tubes, on concave or convex surfaces and many other challenges, can be overcome with one of our unique probes.

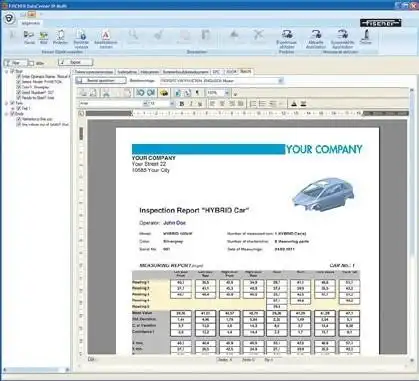

Inspection plan for FMP® 100 and 150

Contact us now for more information

Whether you know what type of machine you require or have questions surrounding our product range, we are always happy to assist.

Get in touch and we will help you find the Fischerscope Instrument that best suits your needs. Our team has many years of experience and is always happy to answer your questions.

If you’d prefer to leave your details, please use the form below and we’ll get in touch as soon as we can.