For most electronics applications it is prohibited to use solders that contain lead (RoHS and WEEE directives). However, the so-called tin whiskers that sometimes grow from the surface of unleaded solder can cause short circuits – posing an unacceptable risk for high reliability (“hi-rel”) applications in aerospace and military use. To prevent this defect, a minimum lead content of 3 wt% is specified for solder used in hi-rel applications. Because the consequences of failure could be so dangerous, these specifications must be verified through measurement of the lead content.

Since the implementation of the EU directives RoHS and WEEE, lead-free solder is in common use for electronics in industrial and commercial applications. However, when exposed to stress or harsh environments (such as high humidity, vibrations, temperature variations, etc.), pure tin is susceptible to forming “whiskers” – hair-like, electrically conductive, crystalline structures of tin that grow from the metal’s surface. While tin whiskers are very thin (typically about 1 µm in diameter) their length can reach several millimetres. Numerous electronic system failures have been attributed to short circuits caused by tin whiskers that bridge closely-spaced circuit elements maintained at different electrical potentials.

Specifications for electronic components used in healthcare, aerospace and military applications therefore require a minimum of 3 wt% Pb in solder alloys to prevent the formation of tin whiskers.

Tin whiskers can cause electrical shorts between circuit Elements.

To prove that hi-rel products have been manufactured correctly, the lead content in the solder needs to be controlled and verified. A quick, reliable and non-destructive test to ensure it contains at least 3% lead or other alloying elements can be accomplished using the X-ray fluorescence method.

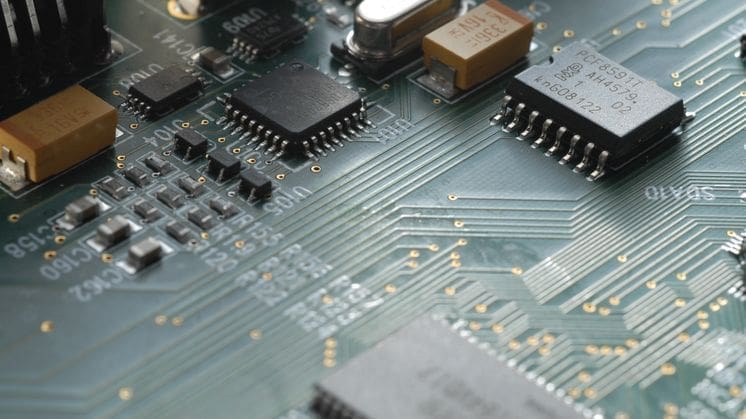

With the FISCHERSCOPE® X-RAY XDAL® it is straight-forward to measure the composition of solder alloys quickly and accurately. For example, a fast scan tells the operator if incoming parts pass inspection, eliminating the risk of mixed lots of solder. Even in rework and repair, it is indispensable for confirming the use of suitable solder. In addition, the XDAL® can be programmed for efficient screening of printed circuit boards.

The FISCHERSCOPE® X-RAY XDAL® is the ideal instrument for determining lead content in solder alloys.

The powerful software of the XDAL® simulates the entire spectrum of a defined measurement application and compares it to the spectrum actually detected, allowing accurate measurements even without calibration standards. This is especially important considering the limited shelf life of many solder alloys with lead (SnPb): In just a few years, these alloys undergo some diffusion effects (clustering of Pb) that make older standard samples often unsuitable for calibrating measurements (see Tab.1). However, FISCHER produced own SnPb standards under special manufacturing conditions to significantly reduce the aging effect.

| SAMPLE | AGE OF SAMPLE (YRS.) | PB CONCENTRATION (WT%) | ||

|---|---|---|---|---|

| nominal | XDAL | Standard deviation | ||

| SnPb3 | < 1 | 3.1 | 3.0 | 0.05 |

| SnPb3 | 3-4 | 3.0 | 2.8 | 0.11 |

| SnPb8 | 8 | 8.5 | 7.5 | 0.3 |

| Eutectic SnPb | > 10 | 38 | 33.6 | 1.0 |

Measurement of solder alloys of different ages are taken with the FISCHERSCOPE® X-RAY XDAL®. While a “fresh” standard is met exactly, with increasing age the deviation from nominal values increases.

With the FISCHERSCOPE® X-RAY XDAL® the lead content of electronic components can be easily checked, ensuring that enough Pb is alloyed to prevent the build-up of tin whiskers, thus avoiding potentially dangerous short circuits in high-reliability applications. For further information please contact your local FISCHER representative.